|

|

|

realsoft3d@scenegraphics.com

REALSOFT

SALES AND SUPPORT @ SCENE

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

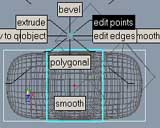

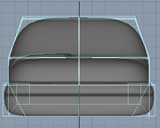

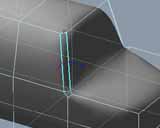

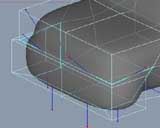

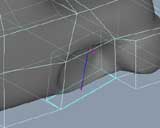

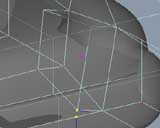

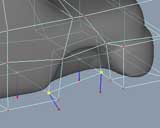

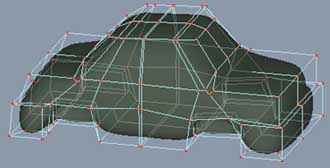

From where the last tutorial left off, run the mouse

cursor over the SDS in edit

mode. Faces are highlighted to show

which face will be selected when

the mouse button is clicked. |

|

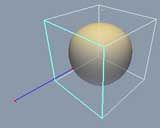

Select the face which corresponds to the left face

relative to your view arrangement.

A handle appears and the face is

highlited. |

|

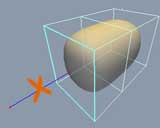

Press the CTRL key and drag on the blue handle to extrude

a face out. You will see that most

common SDS modeling operations are

done using the handles together

with key modifiers. |

|

|

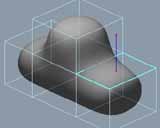

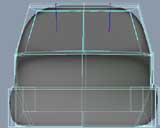

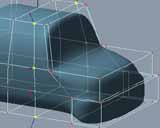

Repeat this process of extruding faces a few more times

to get a very basic car shape. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

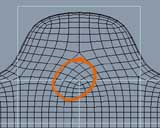

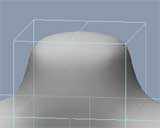

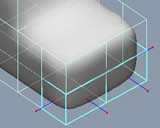

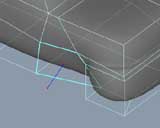

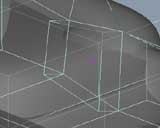

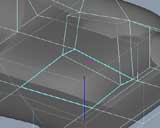

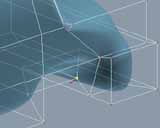

Very important for SDS modeling

-> look at the underlying smooth

nurbs mesh that results from the

SDS control cage. Here we see the

pattern that results from a 'T -

intersection' of edges. |

|

|

|

|

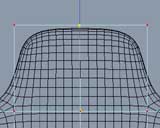

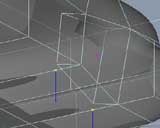

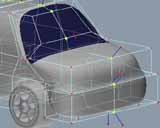

You can quickly change between face/edge and point

editing using the compass menu.

Here is the top view about to go

into point editing to drag a few

points there to get the desired

shape. |

|

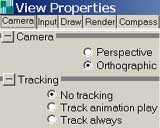

Tip: You may want to go to the view properties and

change some settings for that 'camera'

view that were set up in the last

tutorial, if you prefer modeling

SDS in orthographic views only. |

|

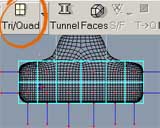

Taking a view from the side of the car, drag-select

faces on the lower half and use

the Tri/Quad tool in the control

bar to subdivide these faces. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

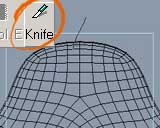

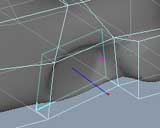

Looking from the side of the model, use the knife tool

from the control bar to split the

edges at the top. |

|

See how the knife tool splits all edges that you draw

through, and creates new edges joining

the intersections. Very useful. |

|

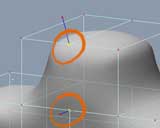

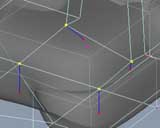

Go into points mode and select the points shown here. |

|

|

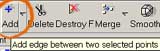

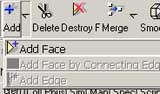

Now, again in the control bar, use the ADD tool to

create a new edge between these

selected points. Repeat this process

for the other side of the car. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

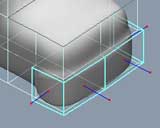

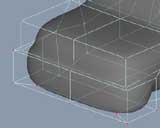

Now look again at the 'flow lines' of the nurbs mesh.

Much more tidy and appropriate for

this part of the model. After some

practice, you will get a good 'feel'

for how to contruct SDS control

cages which result in nurbs meshes

that flow nicely with the contour

of the shape. |

|

|

|

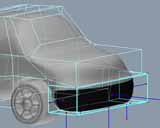

Now to make a simple bumber shape. Select faces shown.

A tip for selecting backfaces without spinning round

to the other side of the model is

to use the comma ',' key while selecting.

It cycles through all faces from

back to front. |

|

|

In the control bar, hit the small triangle next to

the extrude tool to get options

for that tool. Select 'Extrude Face',

and under the 'Action' tab, select

'Selected face vertex'. |

|

|

|

|

|

Split the car down the middle using the knife tool

with grid view and snap on. This

gives a little extra detail to play

with. To perform a straight-line

knife uncheck the freehand option

in the toolabar after selecting

knife tool. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.. and this is the result. The extrude and bevel tools

here are provided when extra control

is needed over just performing those

operations with the handles as was

done previously (with Ctrl-drag

on handle). |

|

Use the compass (same as before) to go into edge mode.

Select the front windshield edge

and bevel it by using crtl-LMB drag

up on the handle endpoint. You

can perform this on both sides at

the same time by selecting both

edges and using bevel on one edge

to get things done faster. |

|

Like you bevelled the edges before, select the faces

on the windshield and bevel those

to give more control over the shape

there. |

|

|

Knife again as shown. Notice how features get a little

sharper as more detail is added

to the SDS cage. The resulting geometry

of all SDS cages is resolved

with clever use of continuous nurbs

patches. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Go back to face mode and select as above - this face

already provides a reasonable starting

point for making the indented wheel

arch. |

|

|

|

There is a very powerful way to achieve sharper definition

to edge/face and points. Each face/edge

and point in Realsofts SDS cage

can be set a weight value. This

is due to the underlying nurbs set

being a complete weighted NURBS

implemetation. Notice here the the

bumber is currently quite smooth

where it joins the main body. |

|

|

|

|

|

|

|

|

|

|

|

|

Go into edge mode and select all the edges where the

bumber shape meets the car body.

To help with this, the hotkey SHIFT

adds selections, ALT removes,

and SHIFT+CTRL toggles. |

|

|

|

|

|

|

|

|

|

|

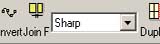

There are a few ways to sharpen at any value you want,

but for now a quick and easy method

to sharpen these edges is just select

the dropdown list in the toolbar

and change from smooth to sharp

Do a quick viewport render - '0'

(zero) shorcut key to see the result

clearly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use the knife tool to make a few new points on this

face close to where the inner part

on the wheel arch is. |

|

|

|

Use CTRL-LMB drag to extrude this face inwards. This

gives nice joining faces at the

sides and top, but leaves us with

some extra faces at the bottom which

have to be fixed up. There's probably

a better way to do this but I chose

to just go ahead and make the extrude

and fix up the details later. So,

to fix up... |

|

|

|

You will see a huge hole in the mesh now. That's fine.

Look at the bottom and notice that

there is actually another face there

extending to the outer edge of the

car. |

|

|

|

|

|

|

|

|

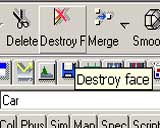

First select this face and destroy it using the tool

shown above. Destroy removes the

face completely, while 'Delete'

will create a new larger joining

face. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Select points and merge as shown above. The shorcut

key to merge points is SHIFT-M. |

|

'Destroy' the large face at the bottom. |

|

Now you can see that a nice framework of points exist

at the correct place (there were many other ways this could have been done). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Select the points in a cycle and add a face. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Basic shape done. |

|

Move a few points around to get the desired shape. |

|

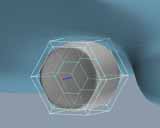

(I won't detail the wheel modelling procedure I used..

it's just using the method I copied

from Hellmut T's wheel tutorial.) |

Here's the finished wheel and a few more point adjustments

made to get a nice circular wheel

arch matching the wheel. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For some quick and easy texturing, I just selected

faces and dropped materials straight

into the viewport. Here the standard

rubber has been dropped onto the

bumber faces and is viewed in OGL. |

|

|

|

|

Another onto windshield faces |

|

|

A few more points are added with knife tool, and various

points are moved around to get a

'front' and 'back' for the car. |

|

Version 4.5 provides a mirror tool based on construction

history for modeling opposite sides

at once. This one was just cut in

half, mirrored and joined with the

'join faces' tool. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

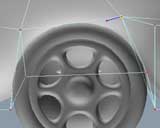

Standard metal and rubber for the wheels and tyres. |

|

.. and a few more materials to suit your taste.. or

whatever .. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Using the basic SDS car body shape, this variation

adds some nurb modeled trimming

and booleaned-out windows. Nurb

objects can be used to cut out of

SDS shapes & analytics, and

visa-versa quite interchangably. |

|

|

|

|